B-Range

POST TENSIONING

Freyssinet has developed compact prestressing systems suitable for prestressing thin elements. These systems make it possible to significantly improve the slabs commonly used in buildings.

Main benefits

- Larger slab spans require fewer columns, providing great freedom in terms of

layout; - Depending on slab type, elimination of soffits or reduced floor thicknesses. The saving in height thus obtained can result in an increase in the number of storeys in the structure;

- Savings in materials (concrete and steel);

- Foundations are smaller and simpler;

- Shorter lead times due to fast installation.

As well as:

- Elimination of deflection in routine service;

- Reduction in number or even elimination of slab contraction joints and floor expansion joints;

- Better control of shrinkage cracking for improved watertightness and hence greater durability.

The use of floors prestressed by post-tensioning results in a 20% reduction in greenhouse gas emissions compared with traditional reinforced concrete designs.

A variety of applications

Freyssinet prestressing systems can be used in floors, foundation slabs and building transfer structures, as well as in industrial slabbing systems. They are a cost-effective, reliable solution for optimising a wide range of structures:

- Residential buildings;

- High-rise office buildings;

- Shopping centres;

- Underground or above-ground car parks;

- Hospitals;

- Schools;

- Business centres;

- Industrial buildings;

- Sports halls;

- Docks, etc.

A VARIETY OF APPLICATIONS

Building floors

These are often thin slabs, continuous over several spans and resting on columns at certain points. Prestressing increases slab bending strength relative to permanent loads and variable loads. Tendons can be arranged in two orthogonal directions or in a preferential direction with added passive reinforcements at right angles.

The benefits brought about by prestressing in building floors are numerous:

- For high-rise buildings:

- Height between floors reduced to the minimum, enabling material savings to be achieved in vertical elements, structural or otherwise;

- A shorter construction cycle on each storey, reducing the overall project lead-time and the amount of formwork;

- The lowest possible floor mass, reducing the loads transmitted to the foundations and loads in cross-bracing when subject to seismic stress.

- For buildings with large plan dimensions:

- Larger column-free areas, which are more functional and allow for better use of space;

- For certain commercial or industrial buildings, deflection and crack opening are strictly controlled.

Foundation slabs

Foundation slabs are in direct contact with the ground and enable buildings to be erected on soils with poor mechanical properties.

The undulating layout of the prestressing compensates for permanent and variable loads. The permanent compression of the concrete also improves foundation slab sealing against any water ingress.

Transfer slabs

Transfer structures are often very thick slabs, subject to heavy loading, which absorb the loads from columns above that are not aligned with the columns below. They are generally used in high-rise buildings to clear a space without load-bearing elements or to effect the transition into car park levels.

Prestressing enables the height of transfer slabs to be substantially reduced; in certain cases Freyssinet will be able to offer high-strength tendons equipped with anchors from its C system for civil engineering structures.

Industrial slabs

These slabs bear directly on the foundation soil. The prestressing tendons are straight, centred and arranged in both directions. They allow for the reduction or even elimination of passive reinforcements in the main run of the slab. They improve bending strength and ensure shrinkage cracking is kept under control.

Freyssinet builds very large industrial slabbing areas, while reducing in number of or even eliminating contraction joints. These joints are vulnerable to wear due to traffic and their elimination is particularly appreciated where automated conveyor systems are installed, for which surfaces must be absolutely flat.

The permanent compression of the concrete by prestressing provides concrete foundation slabs with improved watertightness.

Phased work means that disruption can be reduced to a minimum for the operator.

PRESTRESSING DESIGN

Working closely with the architect and the design consultants in charge of the overall design of the project, Freyssinet revises the design then conducts a detailed study of the floors, supplying all the calculation data required for sizing the vertical elements in particular. Freyssinet is also available to put forward optimised variants of the basic reinforced concrete systems.

In order to reduce the thickness of the slabs and fully or partly eliminate passive reinforcements, Freyssinet uses professional, recognised 2D or 3D finite element design software that complies with regulations and local practice, in order to determine floor dimensions.

Right from the preliminary phase, these design programs make it possible for quantities to be fully verified and calculated precisely:

- for slab floors, punching shear strength due to permanent and service loads;

- for slabs on beams, deflection due to service loads on their own, or even shear forces or cracks opening up.

Bonded prestressing

Prestressing by post-tensioning is generally of the bonded type, i.e. made up of steel strands housed in a duct, which is injected with cement grout after tensioning. This arrangement enables strand loads to be transferred to the concrete structure by bonding, which allows for passive reinforcement to be optimised and significantly reduced.

Among other benefits, internal prestressing in concrete makes it possible to guarantee an improvement in fire protection and ensures that tendons can be re-anchored in the event of openings being made at a later date.

Unbonded prestressing

For projects involving specific stresses, Freyssinet can also offer unbonded prestressing made up of greased sheathed strands installed in the reinforcement prior to concreting. The strands remain mechanically independent of the structure throughout the service life of the structure and slide freely in the concrete.

Unbonded prestressing reduces the space occupied in the thickness of the slab and offers greater freedom in horizontal alignment.

Prefabrication

If appropriate, Freyssinet can put forward a mixed system combining prefabricated elements with prestressed elements cast in situ to optimise lead times and reduce costs.

Rules for preliminary sizing of prestressed concrete floors

The table below describes the main types of prestressed concrete floors and can be used for fast preliminary sizing.

| Diagram | Service load (kN/m²) |

L/h ratio (with passive reinforcements) |

|

|---|---|---|---|

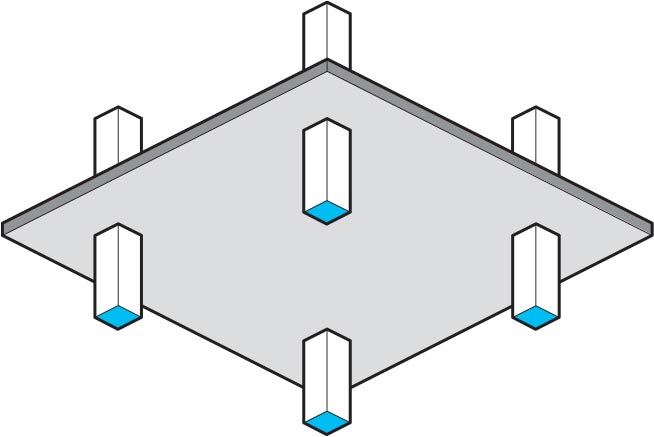

| Slab floor (load-bearing in both directions) Relatively light or medium service loads. |

|

1.5 | 45 |

| 2.5 | 40 | ||

| 5 | 35 | ||

|

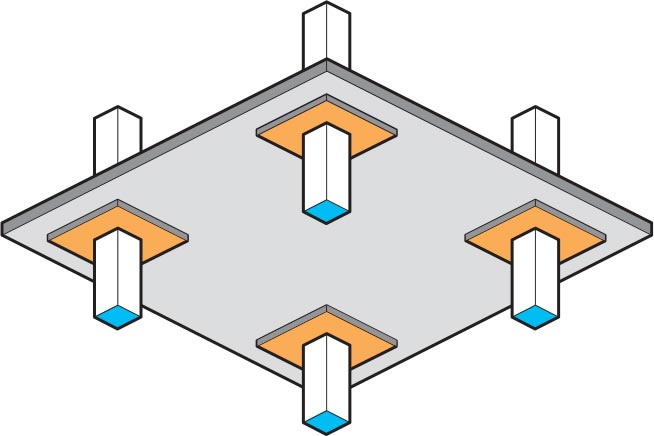

Slab floor with capitals Same applications but for larger spans and medium service loads. Capital drop between 0.75 h and 1.5 h and overhang between 3 hand 6h. |

|

1.5 | 50 |

| 2.5 | 45 | ||

| 5 | 40 | ||

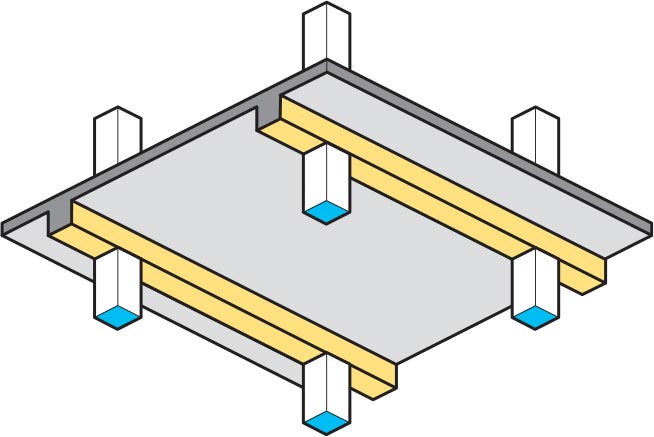

| Slab load-bearing in a single direction Recommended for floors with a prevailing span in one direction. |

|

1.5 | 55 |

| 2.5 | 45 | ||

| 5 | 35 | ||

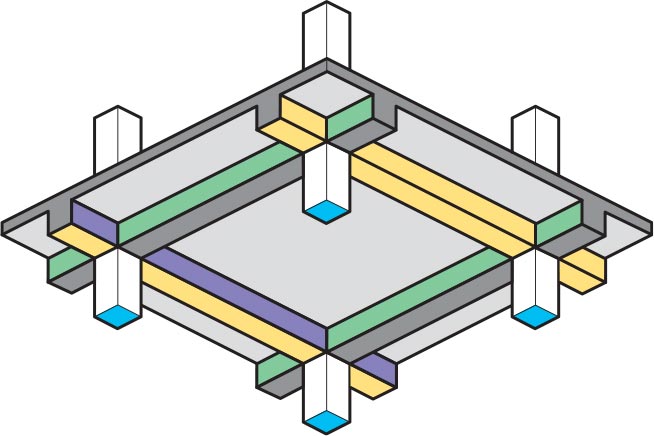

| Slab load-bearing in both directions Spans approximately equal in both directions. |

|

1.5 | 70 |

| 2.5 | 60 | ||

| 5 | 50 |

MULTI-STRAND PRESTRESSING

Type B Active/Passive Anchors

The Freyssinet type B prestressing system consists of internal prestressing tendons with 3 to 5 T13 or T15 strands.

Type B anchors consist of active or passive anchors; they are made up the following elements:

- A cast trumplate embedded in concrete that distributes the prestressing load into the structure;

- A block and its jaws, bearing on the trumplate, which anchors the strands.

The construction provisions stipulated in the project must comply with current local regulations, as well the technical specifications, Freyssinet procedures and technical approval, as appropriate, relating to the use and installation of a type B prestressing system.

Bonded prestressing

In this configuration, type B anchors are used with uncoated strands in a metal or plastic corrugated flat sheath, for ease of insertion into thin elements. The strands are threaded into their ducts prior to concreting in order to overcome duct crushing problems, which might subsequently impede strand threading.

Once the strands have been tensioned and excess lengths cut off, the duct is injected with cement grout.

Unbonded prestressing

For specific projects, system B anchors can be used with strands protected with grease, coated with an individual HDPE sheath, in order to effect unbonded prestressing. The strands are then incorporated directly into the reinforcement, before concreting.

Once the strands have been tensioned and excess lengths cut off, the anchor is injected with cement grout.

C-Range

HIGH DURABILITY PRESTRESSING

A pioneer in prestressing, Freyssinet has continually innovated over the years, and now offers the ultimate prestressing system combining high performance with durability.

Freyssinet’s technical services design anchors, jacks and installation equipment, and also operate a test centre (including a 2,000 tonne tensile testing rig) and a laboratory for the formulation of prestressing grouts.

In order to guarantee high quality service to all of its clients around the world, Freyssinet manufactures its anchors at its industrial subsidiary FPC (Freyssinet Product Company) and operates a central bank of site equipment.

Freyssinet also trains its teams in installing prestressing at all of its subsidiaries. The PT Academy is Freyssinet’s prestressing training school. Each year graduates of the school obtain qualifications certifying their skills as Works Directors, Prestressing Installation Specialists and Operators.

Freyssinet prestressing anchors, ranges C and F, have been proven in structures the world over to comply with the most stringent requirements: bridge decks and piers, nuclear reactor containment vessels, liquefied natural gas storage tanks, offshore platforms, wind towers, etc. Freyssinet has developed an optimised solution for every application.

EUROPEAN TECHNICAL APPROVAL (ETA) AND CE MARKING

Freyssinet has European Technical Approval (ETA) No. 06/0226 for its prestressing process comprising anchor ranges:

- C for 3 to 55 strand tendons,

- F for 1 to 4 strand tendons.

It has also obtained CE Declaration of Conformity no. 1683-CPD-0004. The European Technical Approval was issued in particular after performance of the tests defined in ETAG 013 (European Technical Approval Guidelines for post-tensioning kits for prestressing of structures). ETA and CE marking are subject to continuous monitoring by an official body.

The prestressing kit includes all of the elements that make up a complete tendon.

Specific components

- Passive and active anchor blocks

- Fixed and mobile couplers

- Jaws

- Trumplates

- Protective covers

- Plastic sheaths

Standard components

- Metal sheaths and ducts

- Prestressing strands

- Corrosion-resistant protective materials

For practical reasons, hoop reinforcement is normally provided by the General Contractor.

Designers must check that the provisions adopted for a particular project based on elements in this brochure comply with any local regulations in force.

Sioule Viaduct, France

C RANGE HIGH STRENGTH PRESTRESSING

Application categories

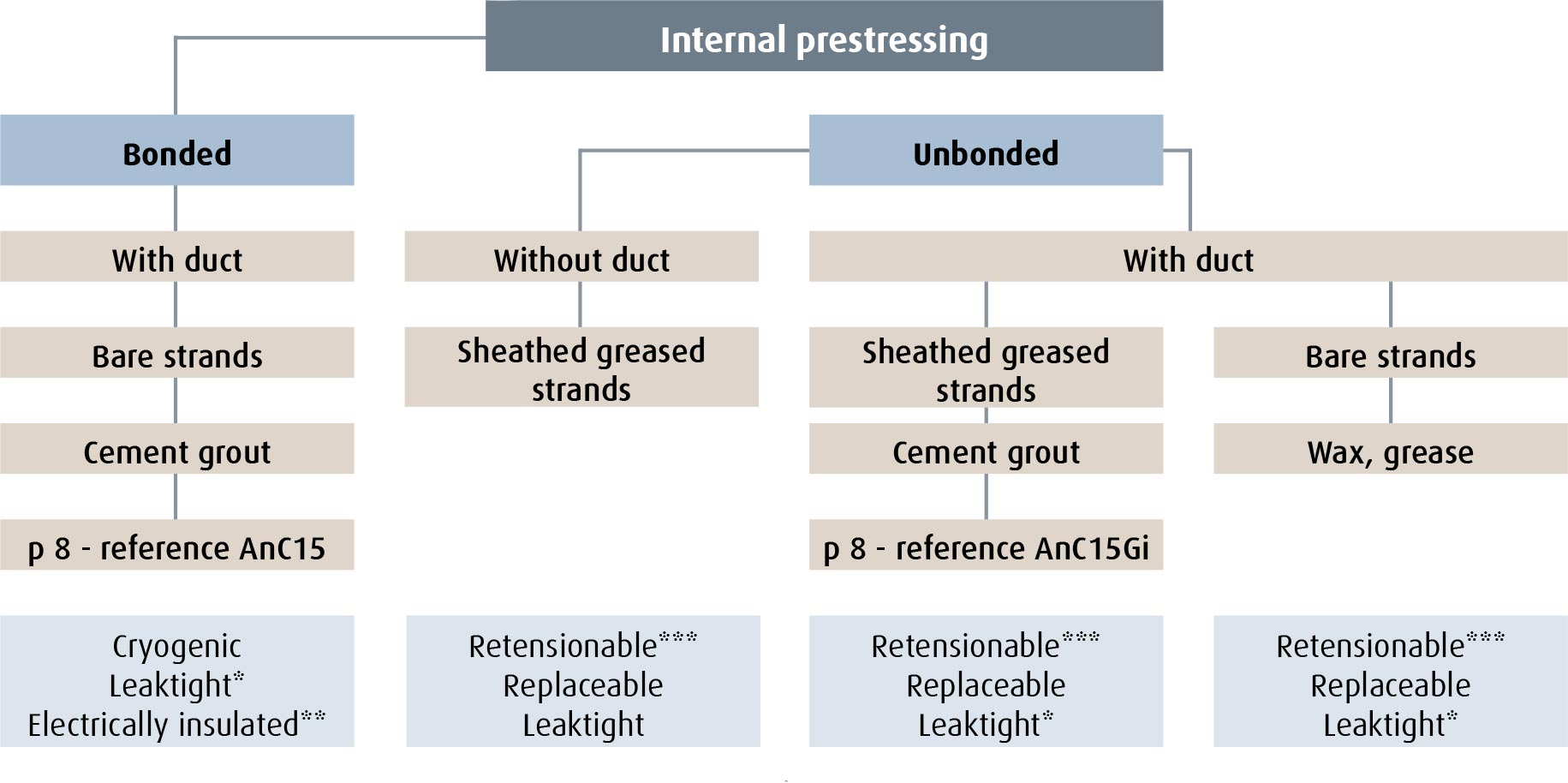

The C range prestressing system is designed and certified for a wide variety of applications:

- use of 13mm and 15mm strands of all grades (1,770 or 1,860 MPa) including galvanised strands or greased sheathed strands

- prestressing units holding up to 55 strands

The system can be used in internal or external prestressing for concrete,

steel, timber or brick structures:

- bonded or unbonded,

- with or without ducts,

- retensioning possible,

- replaceable,

- replaceable, adjustable,

- detensioning possible,

- with electrical insulation,

- for cryogenic applications.

*if there is continuous leaktight sheathing **given special provisions – page 9 ***if strand overlengths are retained

Bonded internal prestressing configurations

The most common use of C range anchors in bonded internal prestressing is based on the use of lubricated, uncoated strands in a corrugated metal sheath, galvanised or ungalvanised, bendable by hand and injected with cement grout after tensioning of the strands. In curved sections and to reduce the coefficient of friction between the strands and the sheath, Freyssinet offers factory lubrication of the corrugated metal sheath using a unique Freyssinet process known as LFC.

To increase the durability of the prestressing or for applications in very aggressive environments in terms of corrosion of prestressing steel, it can be advantageous to replace the corrugated metal sheath with a leaktight plastic sheath (as well as its interconnections). Freyssinet has developed the Plyduct® prestressing duct, a HDPE sheath with a corrugated profile to ensure bonding of the tendon to the structure. Sheath thickness is chosen depending on the lateral pressure exerted

in the curved sections and the movement of the strands during tensioning.

For structures on maritime sites, Freyssinet also offers a leaktight steel duct made up of very thick, plain steel tubes with robust joints created by lapping and resin sealed by means of a heat-shrink sleeve.

For structures made of precast elements with match-cast joints, Freyssinet has developed the Liaseal® sheath coupler. This plastic coupler is watertight to prevent seepage of water between segment joints.

For each configuration there is an appropriate anchor head protection method: this can be done by sealing (concreting the anchor head into a recess), via a permanent cover made of cast iron (galvanised or painted), or plastic, injected with the same protection product as used in the main run of the tendon.

To protect tendons from stray currents or for electrical checks on watertightness of plastic sheaths, Freyssinet offers an electrically insulated prestressing system based on the use of an insulating plate under the anchor head with a plastic sheath and cover to create a permanent, watertight casing completely enclosing the strands.

Unbonded internal prestressing configurations

Unbonded prestressing tendons are mainly used in applications where the tension of the tendon needs to be measured, or where it may need to be retensioned, detensioned or replaced.

To achieve unbonded prestressing it is possible simply to use a flexible, corrosionresistant protective product instead of the cement grout, normally grease or wax specially designed for this purpose. Special attention is then paid to the leaktightness of the ducts.

To increase the durability of the prestressing by using a number of corrosion protection barriers or to allow, for example, for individual strands to be replaced, Freyssinet recommends the use of grease-protected strands, covered with an individual HDPE sheath. These bars can be placed inside a duct injected with cement grout before tensioning the tendon or incorporated directly into the reinforcement before concreting.

Pierre Pflimlin Bridge, Strasbourg – France

External prestressing configurations

External prestressing is well suited to structures made from thin concrete and also allows for easy inspection of the main run of the tendons.

The most common use of C range anchors in external prestressing is based on the use of strands placed inside sections of thick HDPE tube, assembled by mirror welding, which are injected with cement grout after tendon tensioning.

So that a tendon can be removed without damaging the structure, the ducts are of the double casing type at deviators and anchor diaphragms. The HDPE tube runs inside a rigid metal lining tube that separates the tendon from the structure and distributes the transverse loads caused by local deviation.

To produce tendons in which the strands are independent of each other, Freyssinet recommends using grease-protected strands with individual HDPE sheaths placed in a duct injected with cement grout before tendon tensioning. This configuration has the advantage of increasing the durability of the prestressing by incorporating a number of corrosion protection barriers and, for example, allowing for individual strands to be replaced..

Another solution consists in injecting the tendon with a flexible corrosion resistant protective product, a grease or wax specially designed for this purpose. Special care must be taken when hot-injecting these products.

*if there is a continuous leaktight duct

**given special provisions – page 9

***if strand overlengths are retained

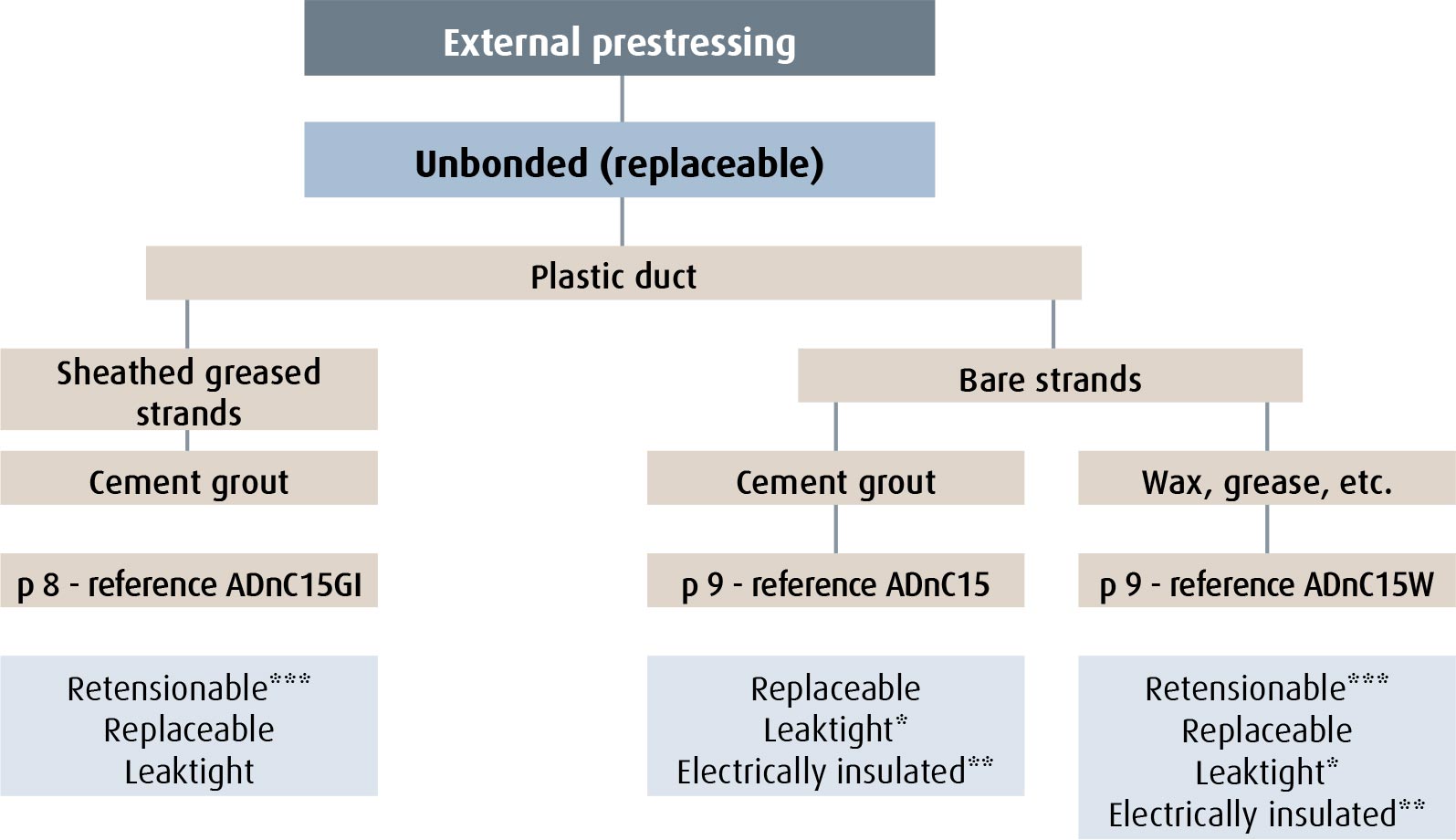

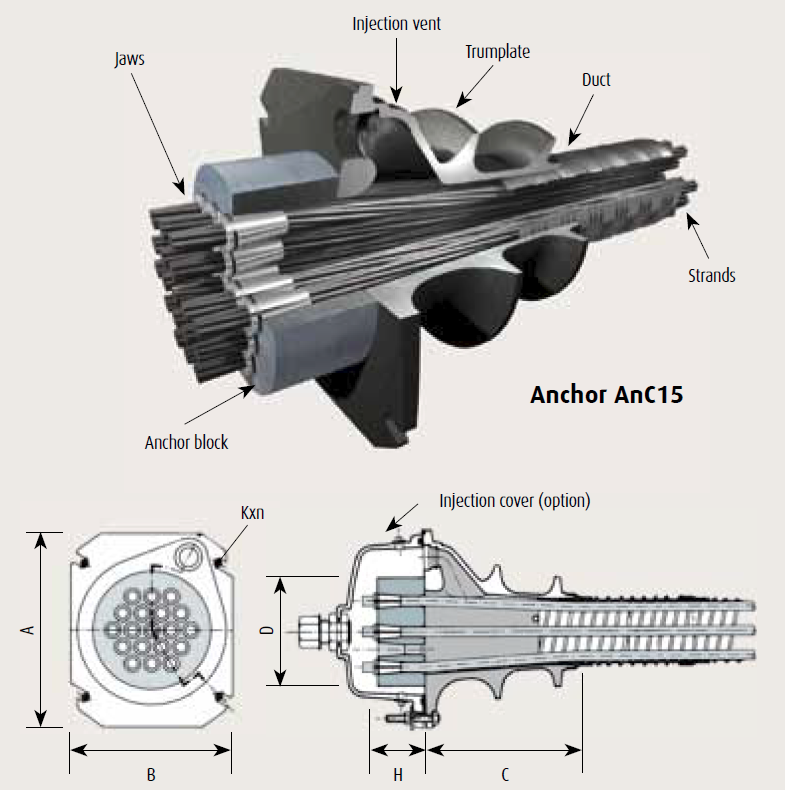

C RANGE ANCHOR

Composition

The anchors comprise:

- jaws guaranteeing high performance anchoring under static or dynamic stresses;

- circular steel anchor blocks drilled with tapered holes;

- multi-ribbed cast iron trumplates for improved distribution of the prestressing force in the concrete;

- optional permanent cover.

Compact anchors

The small size of range C anchors allows for:

- reduced thickness of beams and webs of box girders;

- improved concentration of anchors at ends;

- minimal strand deviation.