With sixty years of experience in concrete repair, strengthening and protection techniques, general contractor for special works Freyssinet offers you a guaranteed turnkey service with Foreva®:

- assistance with diagnosis

- assistance with choosing the rehabilitation solution

- suitability tests

- design

- execution method

- specialist implementation

- monitoring

Freyssinet works with all concrete structures in the fields of civil engineering, ports, harbors and waterways and industrial and historic buildings.

Preventing the Progression of Corrosion

By Galvanic Protection |

|

|

With an anode on the concrete surface (Principle 10 – Method 10.1 – EN 1504) The Foreva® GP Zinc solution is a galvanic protection system that works with an anode on the concrete surface applied by hot spraying of zinc. The large exchange surface of the anode allows for the distribution of uniform galvanic currents. This solution is particularly suited to structures with a medium reinforcement density in aerial environments. This technique lends itself exceptionally well to a wide variety of forms and does not stress the structure through over-drilling or overloading. The protection system is designed on a case-by-case basis depending on the density of the reinforcement to be protected and the service life imposed by the project. |

|

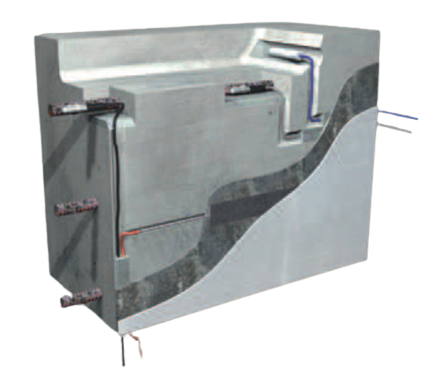

With internal anodes (Principle 10 – Method 10.1 – EN 1504) The Foreva® Galvastar solution is a galvanic protection system that uses discrete sacrificial anodes arranged in a cluster and inserted in the facing in slots near the reinforcement. These anodes distribute a low intensity current and are used for structures with a medium reinforcement density or exposed to low-corrosion environments. This system is particularly suited to areas exposed to damp. The galvanic protection system is designed on a case-by-case basis depending on the density of the reinforcement to be protected and the service life imposed by the project. |

By Cathodic ProtectionForeva® CP solutions are compliant with standard NF EN 12696: “Cathodic protection of steel in concrete”. The anodes are supplied by a low-voltage, regulated direct current generator. They offer effective protection for a number of decades provided they are monitored properly. |

|

|

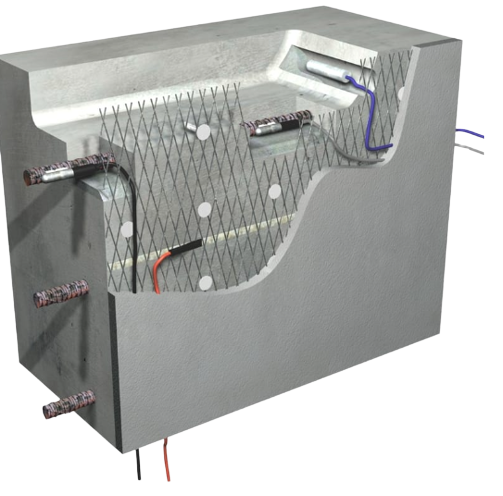

With an anodic mesh (Principle 10 – Method 10.1 – EN 1504) The Foreva® CP Mesh solution is an impressed current cathodic protection system that uses a stabilized titanium mesh anode coated with 2 to 3 cm of shotcrete. The anodes distribute uniform high-density protective currents to the surface of the facing. The solution is suited to both highly chlorinated and carbonated structures and is recommended for treating heavily polluted structures. |

|

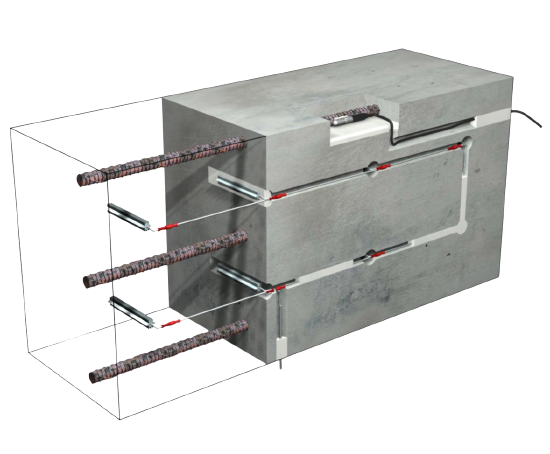

With anodic ribbons (Principle 10 – Method 10.1 – EN 1504) The Foreva® CP Ribbon solution is an impressed current cathodic protection system that uses stabilized titanium anodic ribbons inserted in the facing in slots near the reinforcement. The anodes are perfectly suited to complex facing shapes and allow for the adjustment of current distribution by reducing their spacing. The Foreva® CP Ribbon solution can be used to protect new structures by cathodic prevention by placing the anodes in the reinforcement cage before concreting. |

|

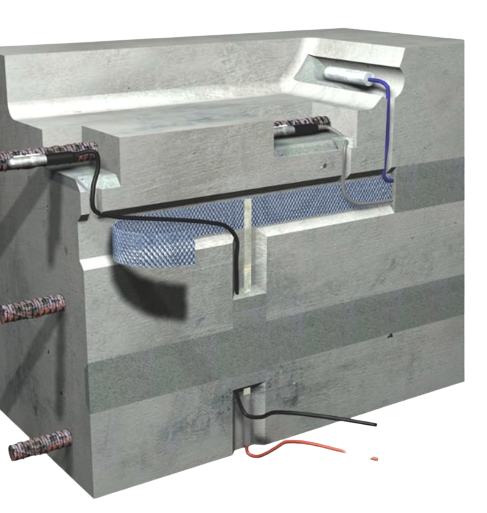

With internal anodes (Principle 10 – Method 10.1 – EN 1504) The Foreva® CP Tube solution is an impressed current cathodic protection system that uses stabilized titanium discrete anodes arranged in a cluster and inserted in the facing in slots near the reinforcement. It can be used to treat areas with high reinforcement density and to protect reinforcements deep in the facing. |

|

With anodic paint (Principle 10 – Method 10.1 – EN 1504) The Foreva® CP Coat solution is an impressed current cathodic protection system that uses an electrically conductive paint as an anode. The anode is well suited to complex facing shapes requiring low-intensity protective currents. Due to their organic nature, the anodes have a limited service life. They can offer effective protection for over 10 years provided they are monitored properly. |