ELASTOMERIC BEARING

A laminated elastomeric bearing is an elastomeric rubber block reinforced with steel plates vulcanized when built. This bearing is the connection between a structure and its support, and should make the following possible through elastic deformation:

- transmission of normal forces;

- horizontal movements;

- rotation of the structure in any direction;

- transmission of horizontal forces, within defined limits.

It may also be provided with a sliding plane for withstanding large movements of the structure and also having a one or two horizontal movement locking systems.

All Freyssinet bearings are CE certified.

APPLICATIONS

Behavior

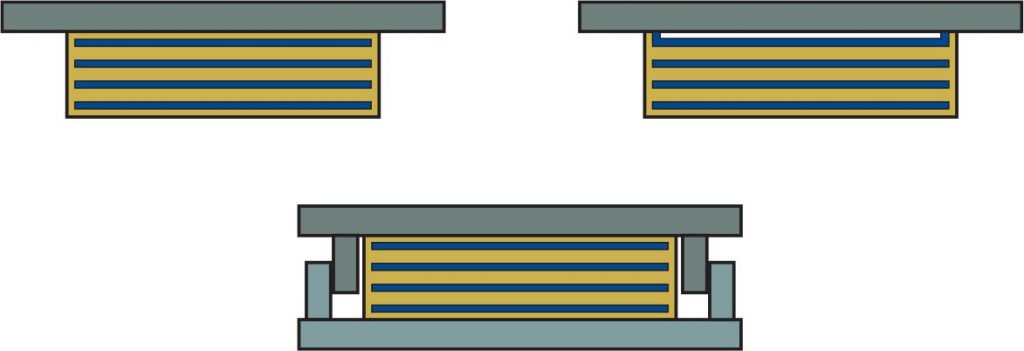

Each elemental layer, subject to stresses and movements, deflects as shown in the three diagrams below:

Shears that occur in the elastomeric layers depend on their dimensions, stresses and also the characteristics of the elastomer used.

Sizing of bearings is based on restricting these shears in accordance with current national or international regulations.

Use

Banded elastomeric bearings are mainly used in the structures field for which this product has many advantages: long service life, reliability, maintenance free, lightness, small overall dimensions and easy to install.

These qualities are also sought in the building field where laminated elastomeric bearings may be used for filtering vibrations (reduction of noise annoyance for example) or even earthquake proof insulators (acceleration reduction).

Installation

Installation quality is a vital condition for efficient operation and long lasting quality. Arrangements should be made at the design stage for providing sufficient clearance around the bearings so they can be monitored and possibly replaced.

ELASTOMERIC BEARING TYPES

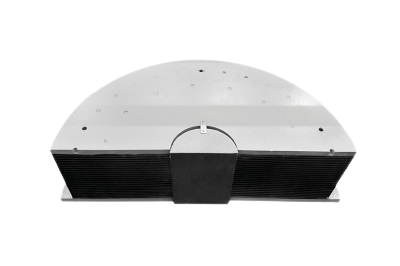

Standard bearings

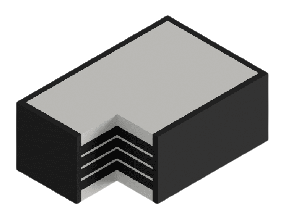

Bearings are individually molded and the reinforcing plates are completely buried in the elastomer with at least 4mm lateral cover and generally 2.5mm thick (type B) outside layers with the exception of bearings provided with thick external bands (type C).

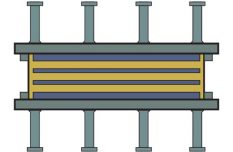

Type B |

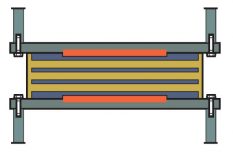

Type C |

These bearings may have a rectangular, square or circular section. They may also have holes for running specific materials through (cross bar anchor), for fitting damping material or for reducing vertical stiffness.

|

|

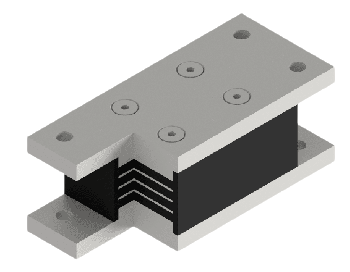

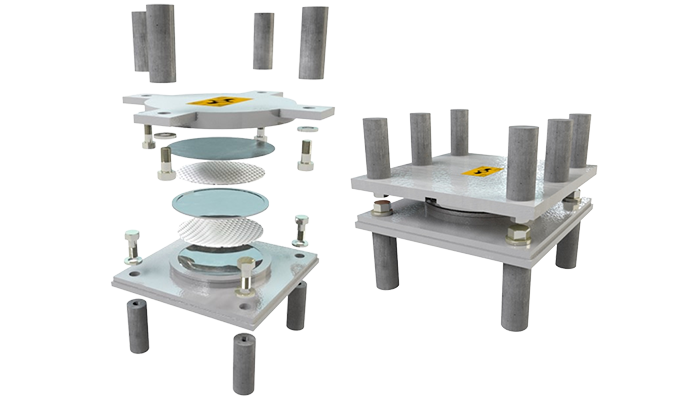

Bearings with anchor plates

Bearings with anchor plates

Freyssinet offers several solutions appropriate for different configurations, considering the variety of construction methods for structures and the stresses transmitted by bearings.

Bearings fitted with corrugated outer plates to guarantee thin connection. |

Bearings fitted with outer plates, anchor plates and connection devices. |

Bearings fitted with outer plates, anchor plates and shear discs. |

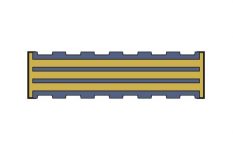

Bearings with sliding surface

Laminated elastomeric bearings can be fitted with a sliding surface comprising a PTFE (polytetrafluoroethylene) sheet dipped in the elastomer (Type D) of the bearing or notched in the top thick outer plate (Type E) and a sliding plate provided with an austenitic steel sheet for decks requiring significant movement. Therefore, the built up bearing only provides very little movement resistance (limited to PTFE/ austenitic steel friction).

Type D |

Type E |

Restrained bearings

Transfer of large horizontal loads in either direction can be provided using steel guides.

Freyssinet offers neoprene and natural rubber based bearings to meet different national or international standards (BS, AASHTO, DIN, EN, etc.). Production quality of these bearings is guaranteed by appropriate formulation, control of mix preparation and steel plate surface treatment quality, as well as by the care applied to construction and molding. Internal and external inspections are made at each production stage.

Moreover, Freyssinet conducts a policy of permanently improving its products and research and development of new processes or materials. The rigorous product quality control practices Freyssinet has developed have enabled the Group to obtain CE marking to distribute its elastomeric bearings.

LRB

ISOSISM® LRB

GENERAL DESCRIPTION

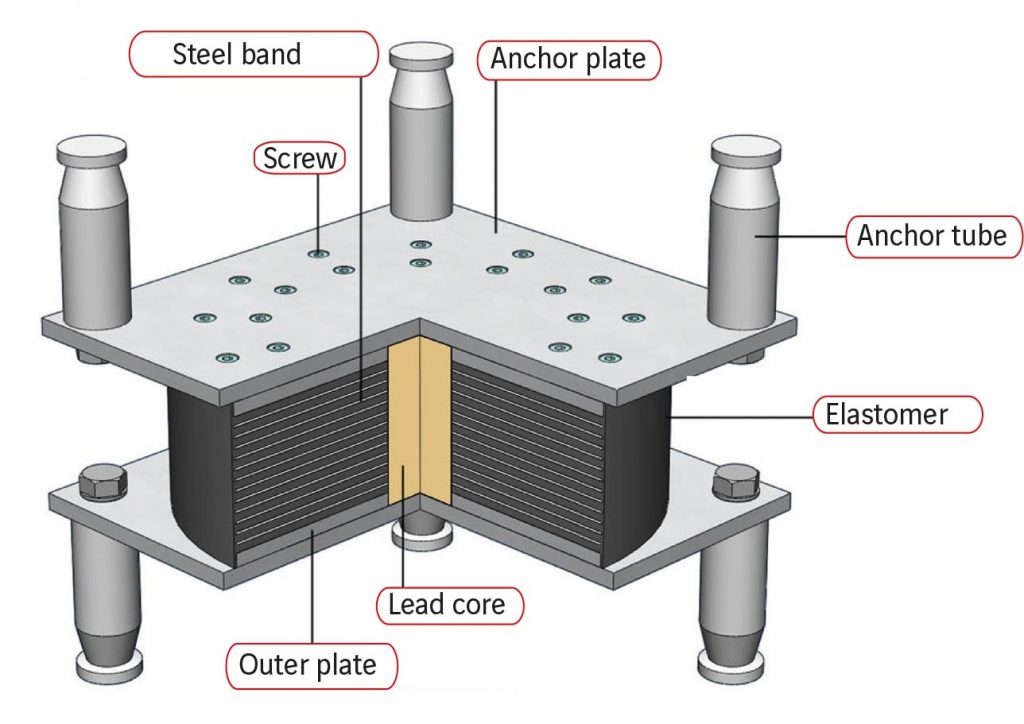

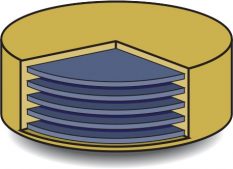

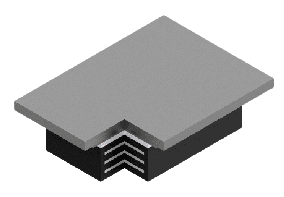

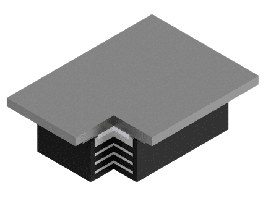

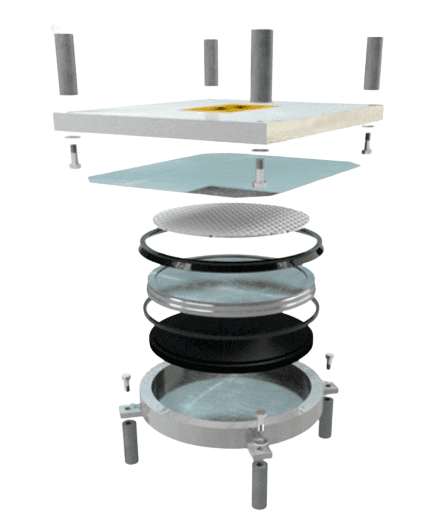

The ISOSISM® LRB (Lead Rubber Bearing) is an isolator designed using an elastomeric block (natural rubber or neoprene) reinforced with metal bands bonded by vulcanizing. It has one or more cylindrical lead cores.

The damping provided by the ISOSISM® LRB results from the nature of the elastomeric mixture and the lead cylinder, and reduces the acceleration (through the distortion of the lead cylinder) and displacement of structures during a seismic event. It is designed and manufactured in accordance with EN 15129.

It is usually a type C isolator (fitted with outer plates) manufactured to the dimensions required for the project. It is available in square or round formats.

APPLICATIONS

The ISOSISM® LRB has numerous applications in buildings, nuclear power plants, civil engineering structures, etc. It isolates the structure from the movement of the ground by forming flexible connections that increase the fundamental period of vibration of the structure to be protected and reduce its acceleration by a ratio of up to 3 to 5.

MAIN PROPERTIES

- High recentering capability;

- High damping capacity (ξ ≤ 30%);

- Moderate maximum displacement;

- Zero maintenance.

Arch Bridge – Basarab – Bucharest

TESTS

ISOSISM® LRBs have undergone numerous dynamic tests to guide and validate Freyssinet’s technical development process.

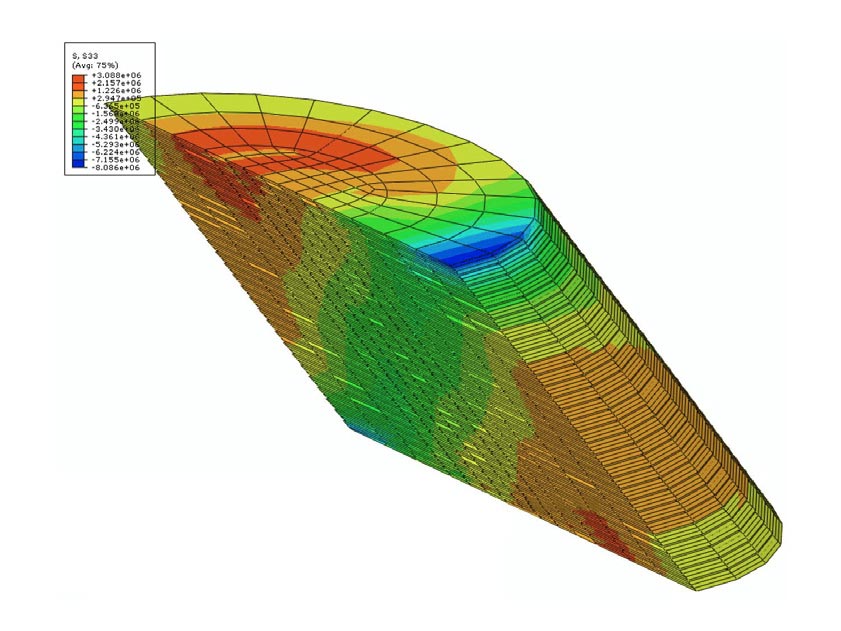

3D modeling of an ISOSISM® LRB

Testing an ISOSISM® LRB

CE MARKING

ISOSISM® LRB isolators can be supplied with CE marking.

FREYSSINET SERVICES

Freyssinet can produce structural designs with earthquake protection devices, including LRB isolators.

DESIGN

In addition to their isolating qualities, these isolators bear the vertical loads of the structure and recenter it after dynamic stress.

BEHAVIOR LAW

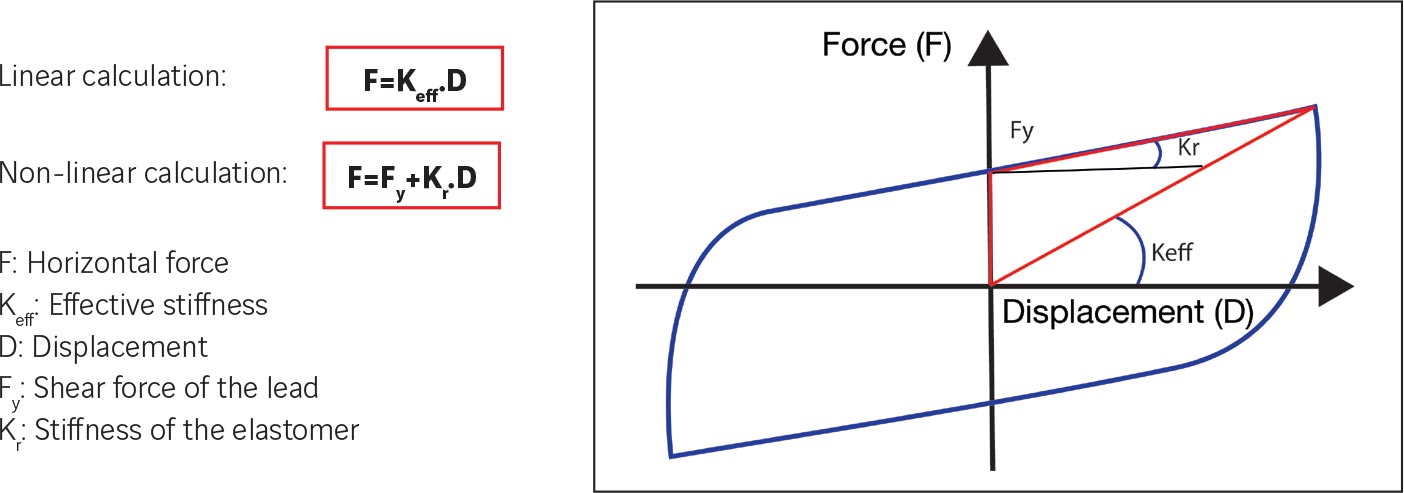

The behavior law of the ISOSISM® LRB can be modeled as follows:

There are two possible structural design approaches:

The damping is obtained by the properties of the lead core and the nature of the elastomer.

GRAPHIC REPRESENTATION

The device can be shown using the following graphic representation in accordance with EN 15129.

| Graphic representation of an ISOSISM® LRB plan view  |

Graphic representation of an ISOSISM® LRB elevation  |

LRB isolators are shown in their deformed position in order to emphasize their lateral flexibility.

RANGE

Two types of mixture are available for different shear modulus G values:

- Model LRB 0.4 – 10: Modulus G=0.4 MPa

- Model LRB 0.8 – 10: Modulus G=0.8 MPa

STRUCTURAL CONNECTIONS

The isolators are connected to steel structures using bolts.

They are connected to concrete structures using anchor tubes or studs.

Sakarya Viaduct – Turkey

TETRON® CD MECHANICAL POT BEARINGS

Tetron CD® pot bearings have been developed by Freyssinet since 1960. They are designed to allow or to block movements between two structures and to transfer the induced reactions. They fully satisfy all current international standards.

The Tetron® CD pot bearings designed according to the EN 1337 standard are all CE certified (no. 1777-CPD-0703). This EC certificate of conformity attests that all provisions concerning the attestation of conformity and the performances described in the annex ZA of the standard EN 1337-5 were applied and that Tetron® CD pot bearings fulfill all prescribed requirements.

TETRON® CD design

Field of use: building and civil engineering works.

Types: fixed bearings, guided sliding bearings and free sliding bearings.

Minimum operating temperature: -35°C for sliding types and–40°C for fixed type.

Elastomeric pad: diameter less than or equal to 1500 mm.

Seals: Three types of internal seals are allowed for the Tetron® CD bearings:

- Brass seal for accumulated sliding path of 500 m

- Stainless steel seal for accumulated path of 1000 m

- Carbon filled PTFE seal for accumulated path of 2000 m

Upon request Freyssinet designs special bearings:

- to withstand specific loads: seismic, uplift, etc.,

- or to add options: load monitoring, jackable, etc.

FUNCTION

Tetron® CD pot bearings developed by Freyssinet incorporate confined elastomer disks. They form the mechanical connections between a structure and its supports.

These bearings have the following advantages:

- resistance to low to very high vertical loads;

- transmission of high vertical and horizontal forces within small overall dimensions;

- high amplitude movement capacity in one or two horizontal directions with a very low coefficient of friction and without any elastic return force;

- high rotational amplitude along any horizontal axis, with a low resisting moment;

- very high resistance to dynamic loads.

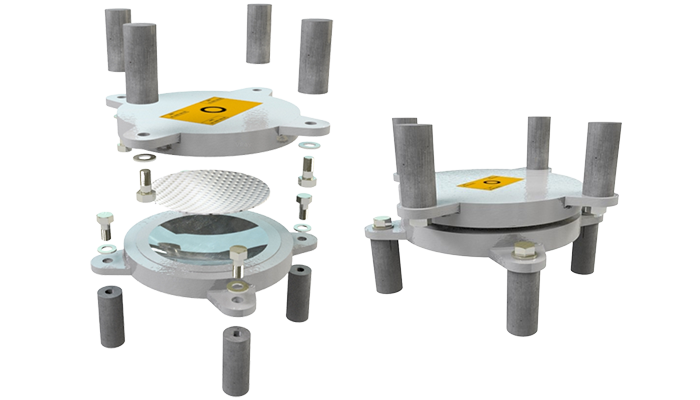

DESCRIPTION

The Tetron® CD pot bearing is composed of an elastomer disk confined in a cylindrical space limited by a hollow base (the pot) and a piston.

The elastomer behaves like an uncompressible liquid. It can thus transmit very high loads and absorb rotations of the structure. If the pot bearing is provided with a sliding plate, it becomes multi-directional and a guide can be added to make it single directional.

THERE ARE THREE AVAILABLE POT BEARING TYPES:

Tetron® CD Fixed Bearing (FX)

Tetron® CD Fixed Bearing (FX)

This type consists simply of a pot, a piston and an elastomer disk.

The Tetron® CD FX pot bearing behaves like a point hinge and can transmit horizontal forces along any direction either by friction to the structures or by anchor devices.

Tetron® CD Free Sliding Bearing (GL)

Tetron® CD Free Sliding Bearing (GL)

This type consists of a fixed pot bearing in which the piston is covered by a polytetrafluoroethylene (P.T.F.E) disk on which the upper sliding plate fixed to the superstructure is free to move. The bearing constructed in this manner is free to slide (it is multi-directional) and follows displacements in all horizontal directions.

The Tetron® CD GL bearing is not designed to transmit horizontal loads.

Tetron® CD Guided Sliding Bearing (GG)

Tetron® CD Guided Sliding Bearing (GG)

This type is a multi-directional bearing provided with a guide. This guided sliding (or unidirectional) bearing only enables movements along the guiding direction. The guidance is achieved either by a central guide fixed on the piston or the sliding plate, or by side stops fixed to the plate.

The Tetron® CD GG pot bearing can transmit horizontal forces in the direction perpendicular to the line of guidance.

TECHNICAL SPECIFICATIONS

Tetron® CD pot bearings are designed to satisfy specifications of international standards or more stringent requirements as may be needed for some specific projects.

Materials

The source of materials used to make Tetron® CD pot bearings is certified to technical specifications defined in European standard EN 1337-5 or equivalent.

Protection against corrosion

All metal parts in Tetron® CD bearings are protected against corrosion in accordance with project specifications.

This protection may be provided for example by a paint system that may or may not complement zinc / aluminum or zinc metallization.

Attachments

It may be necessary to fix Tetron® CD bearings to the structures using a removable system, depending on the applied horizontal forces.

This attachment is usually made by sockets embedded in the structures onto which the bearings are bolted.

Options

Tetron® CD bearings may be equipped with the following options on request:

- a P.T.F.E. scraper disk protection seal;

- a skirt to provide optimum protection against external aggression;

- plane or skew external distribution plates;

- a movement indicator;

- a vertical load measurement device;

- temporary equipment for launching bridge deck.

There are other options. Please call a Freyssinet local agent for further information.