ANCHORING SYSTEMS FOR GEOTHECHNICAL ENGINEERING

INTRODUCTION

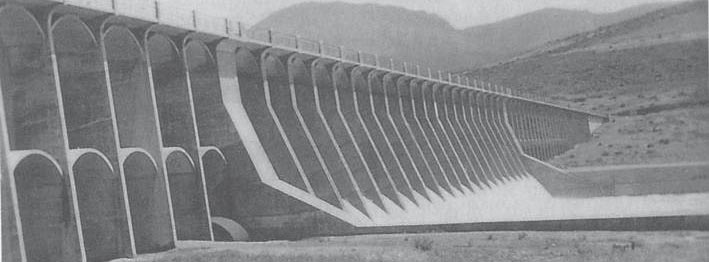

Ground anchors were one of the first applications of Freyssinet’s technologies. In 1939, Eugène Freyssinet used prestressed anchors, together with flat jacks, to stabilize the Beni Bahdel dam in Algeria.

Strengthening of the Beni Bahdel dam, Algeria – 1939

Ever since, technological developments have pushed back the boundaries in this field. The realm of possibilities has increased significantly, enabling both designers and builders to safely and effectively overcome the technical challenges inherent in the environment.

Conscious of the trends shaping demand and the market, Freyssinet has considerably expanded its geotechnical engineering range over the past few years.

With more than 70 years’ experience in soil structure, together with an accredited production force that complies with international standards, Freyssinet designs, manufactures and supports companies on-site.

We can draw on our expertise at every stage in the process to deliver superior performance and future-proof our work.

Freyssinet can provide its expertise and skills to drive your current and future projects:

- Products are developed and then manufactured in modern workshops by skilled workers. Quality is the keyword at every stage in the manufacturing process, and all products undergo exhaustive tests to guarantee best-in-class performance.

- Freyssinet offers anchoring solutions and associated services to companies engineering special foundations and carrying out strengthening work to ensure structural stability and reinforce the ground.

- Freyssinet can advise companies and project managers on structural design, installation methods and specialized technologies. Because each customer is unique, our group of experts provides you with exactly the right solutions for your requirements.

A key player in geotechnics, we pursue an active research and development policy, and our main aim is to gain a clear insight into each customer’s requirements in a bid to deliver the best-fit solutions.

Rosa Parks station, Paris, France – 2012

AREAS OF APPLICATION

Anchors are used in all areas of construction.

|

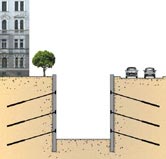

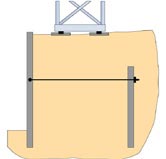

Excavation

The anchor ensures that the ground remains stable and allows for deep, wide excavations. It is often temporary, because the long-term stability of the ground is maintained by the structure built in the excavation (car parks, basements, etc.) |

|

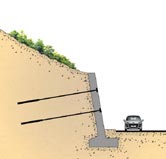

Slope stabilization

Installing anchors at an angle prevents landslides and improves ground resistance. |

|

Dams

Vertical anchors are generally prestressed and improve dams’ rollover resistance, while reducing water seepage along the line of contact with the rock. |

|

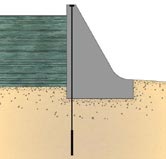

Quay walls

Port tie rods keep a quay wall stable by transferring the forces to a rear sheet pile wall. This principle is also used for backfill held in place by prefabricated walls (access ramps, etc.) |

|

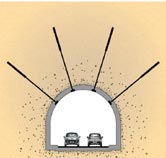

Underground

Anchoring techniques strengthen retention of the galleries by balancing the forces of the ground. This type of application is found in mines and tunnels. |

|

Anchoring structures

Vertical anchors provide an effective link between the foundation and the ground, while curbing the effects of fatigue when prestressed. Anchors can be used for towers, radio masts, wind turbines, etc. |

|

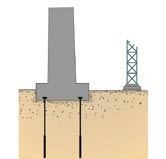

Foundations

Anchors enable structures to be built on land with a low bearing capacity or unstable land. The vertical loads of the structure are transmitted to the deeper, stable areas. |

|

Hydrostatic uplift loads

Corrosion-resistant anchors are used to hold structures in place that are subject to significant water uplift pressure and therefore enable structures to be built in wet areas by compensating for the principle of Archimedes. |

There are several families of anchors for these different applications:

- Ground anchors

- Soil nails and rock bolts

- Micropiles

- Port tie rods

FREYSSIBAR PRESTRESSING SYSTEM

Developed by Freyssinet, worldwide leader in prestressing activities, the Freyssibar prestressing system comprises a wide range of threaded bars and associated anchoring, coupling and extension devices. This prestressing system is adapted to many applications. Among these are :

- Permanent or temporary prestressing

- Holding down bolts for cranes, wind turbines, etc.

- Bridge construction systems

- Ground and rock anchors, rock bolts for geotechnical, mining, tunneling works

- Heavy lifting

- Tie rods for marine works

Freyssinet is the holder of the European Technical Approval (ETA) n° ETA 09/0169 for the Freyssibar post-tensioning kit for prestressing of structures.

The Freyssibar flat anchorages and couplers for fully threaded bars up to 50 mm are approved to the requirements of ETAG 013. Freyssinet has also obtained the EC-certificate of conformity: certificate n°1244-CPD-1014. The ETA and the EC-marking are followed by a notified body.

TECHNOLOGY

The bars

The bars are hot rolled from high strength alloyed steel. They are subsequently cold worked by stretching and then threaded over their full length or on the extremities by cold rolling. The standard range of nominal diameters is: 26.5; 32; 36; 40 and 50 mm. Non-standard diameter bars can be delivered on request.

The fabrication process provides a high quality thread ensuring high fatigue resistance and a low susceptibility to stress corrosion.

The nature of the Freyssibar manufacturing method also ensures that every single bar is stress tested to 85% of the guaranteed ultimate tensile strength of the bar.

The geometry of the thread is specifically designed to ensure ease of use on site, providing fast, accurate and easy tightening.

Bars are available in maximum lengths of 11.8 meters. Beyond this length, extension sleeves allow bars to be connected together.

Lifting : prestressed connection between a segment and a beam.

The anchorages

The anchor devices are designed to anchor the force in the bar and transfer it to the structure. Four types of anchorages are available:

- Standard anchorages with a nut and washer;

- Hinge anchorages using a nut with a spherical seat;

- Standard anchorages using a low rotation spherical nut and spherical washer;

- Fixed anchorages using a threaded end plate.

All nuts are hot forged. Also, couplers allow primary bars to be connected to secondary bars.

The accessories

Freyssinet offers a full range of sheathing that is easy to install. In particular:

- Steel strip corrugated sheath – threaded over its full length, which allows easy and fast connections;

- High density polyethylene tube – with elements mirror welded to achieve a leak free and non corrodible envelope;

- Sheathing accessories – specific to the tensioning and coupling devices, required to fit the coupler geometry. The length of the ducting element used is project specific, so as to allow the coupler displacement over a sufficient length during the tensioning operations.

Anchorage of steel ropes

TECHNOLOGY

Properties

Fatigue : The system has a fatigue resistance in excess of two million cycles of loading over a tensile stress range of 590-670 N/mm2, exceeding the ETAG 013 requirements.

Relaxation : After 1000 hours the loss of stress due to relaxation in the Freyssibar system loaded to 70% Fpk is below 3% which is better than the 4% maximum as described in pr EN 10138-4.

Anchorage strength : Freyssibar post-tensioning system is tested to ensure that the failure load on the bar with coupler and anchorage is more than 95% of the strength of the bar alone.

Protection against corrosion

Stress corrosion tests have been performed in accordance to prEN 10138. The bars have been stressed under corrosive environment during 500 hours and passed the subsequent tensile test to failure. Freyssibar is not susceptible to stress corrosion but depending on the conditions of exposure, a specific corrosion protection can be applied under request.

The corrosion protection system is selected in accordance to the expected design life time and the conditions of exposure.

Permanent ties for quay walls

Surface coating

- Hot dip galvanizing after sand blasting (no risk of hydrogen embrittlement due to acid pickling)

- Metallization (Dunois, etc.)

- Petrolatum tape

- Epoxy coating

Specific injection products

- Wax : hot injection ( Allow for subsequent re-tensioning of the bars )

- Grease ( Allow for subsequent re-tensioning of the bars )

- Cement grout : alkaline environment

Ducting

- Corrugated ducts: light and easy to install

- Smooth pipes: stiff and resistant to shock

Ducts and pipes can be either in steel or in HDPE (non corrodible).

Different protection systems can be combined to enhance the degree of protection.

Quality control

The fabrication of the bars and the anchorages is carried out under a quality assurance system in compliance with the quality standard ISO 9000 : 2000. Flat anchorages and bars have passed all the tests required in ETAG 013.

Prefabricated bar tendons

Ground anchors

For over 50 years Freyssinet has been involved in the construction of buildings and skyscrapers, optimizing their structure though the benefits of prestressed floor technology.

With its integrated prestressing design, supply and installation solutions, Freyssinet makes its expertise and know-how available to contracting authorities and architects to design ever more functional and durable structures, while taking implementation constraints into consideration.

Technical support from the architectural design phase

Contemporary architectural favor large uninterrupted floor areas, flexible internal layout and spaces that are easy to modify and move around in, while considerably improving the durability of buildings. All of these requirements can be met through the use of prestressing by post-tensioning, which enables the creation of large unobstructed floor areas with a minimum number of columns and reduced floor thickness.

Freyssinet supports its customers from the design stage in order to optimize structures with a view to cutting construction costs and lead times, while meeting their architectural requirements.

Complete integration of prestressing works into the construction cycle

When prestressing operations from part of the construction program, the constraints associated with scheduling and phasing the works constitute a major challenge. Freyssinet’s numerous strengths means that it is able to guarantee its customers a quality service performed in strict accordance with production cycles:

- The Freyssinet prestressing system, which is CE certified and marked, has been designed for high on-site productivity;

- Freyssinet-designed installation equipment enables fast, high-quality execution;

- Freyssinet’s specialist teams meet the training and qualification requirements of standard CWA 14646.